Noise Mitigation Deployment System for fast positioning of subsea hydro dampers

After successfully delivering our in-house designed Noise Mitigation Deployment System (NMDS), we look back at this amazing project. Our client – a Dutch heavy lift contractor – needed to install WTG and OSS monopiles in German waters. To be compliant, a hydro sound damper system was needed during monopile installation. In April 2021 we received the contract to design the deployment system of this noise reduction device. During the engineering phase, we were also awarded the fabrication scope.

GOAL

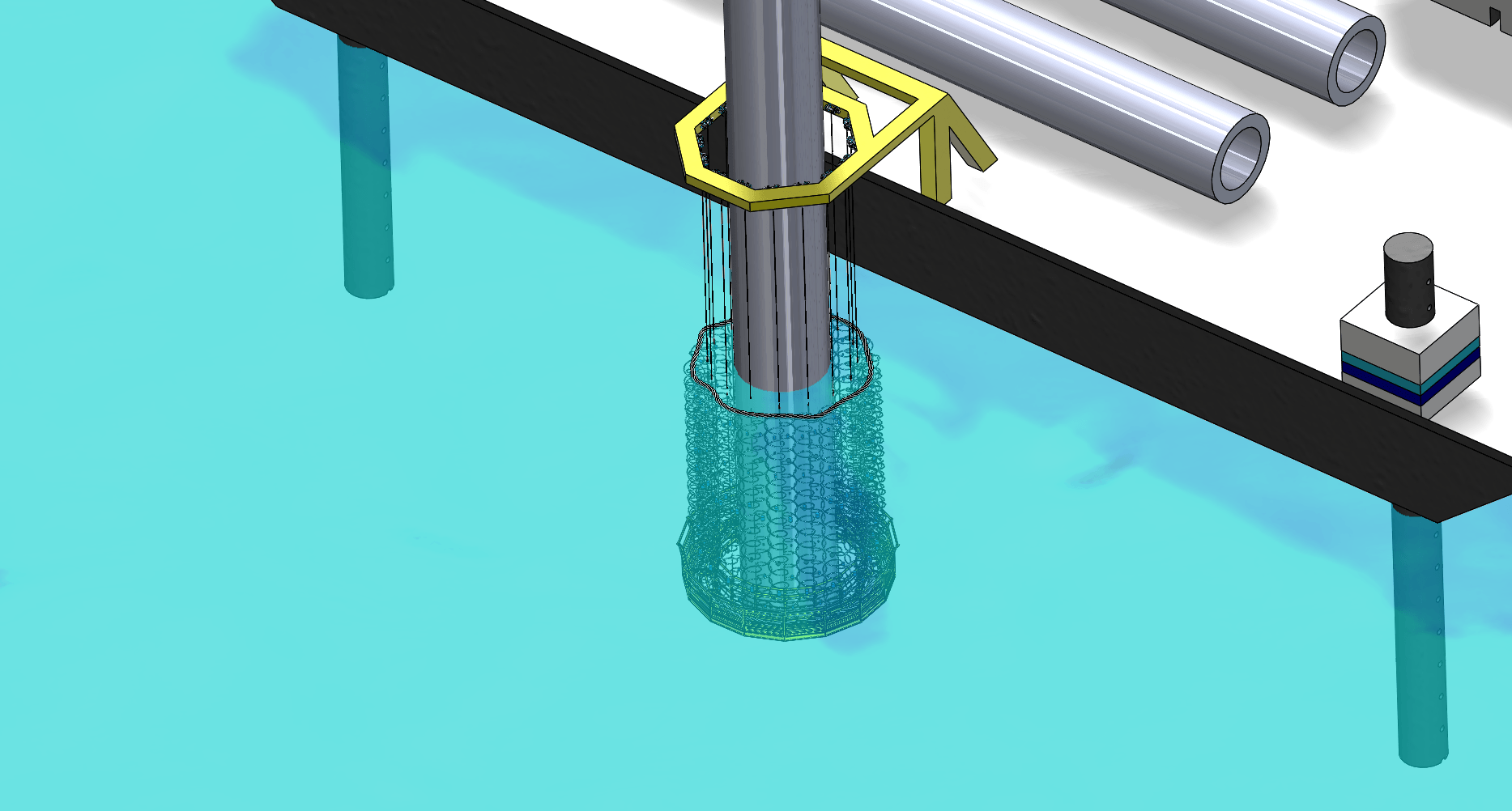

Our objective: to design, build and deliver a Noise Mitigation Deployment System – including hydraulics and controls – that flawlessly integrates with the monopile gripper of the offshore installation vessel. The deployment system consists of a basket for the hydro sound damper net and eight skids with winches to handle the basket with the net.

Image courtesy: OffNoise-Solutions

SEAMLESS INTEGRATION WITH EXISTING INTERFACES

Designing an NMDS is one thing, but seamlessly integrating it with existing interfaces is another. To integrate this system with the monopile gripper, we needed to figure out how to connect the doors of the noise mitigation system with the doors of the monopile gripper. A challenge here was to create a simultaneous movement of gripper and basket doors without any clashes of the interfacing equipment.

Another interesting challenge was the basket itself. The net of the hydro sound damper was folded into the basket. The basket was placed under the gripper and could be lowered into the sea through 18 winches. Hence, the weight of the basket is a crucial aspect. It had to be heavy enough to bring the net down (keeping in mind the buoyancy of the HSD net), but could not weigh more than the gripper could handle.

Skids for the CT winches

FABRICATION

As the design was taking shape, another process started: the fabrication of the entire system, working in close cooperation with our subcontracters for hydraulics, controls and steel manufacturing. Over the last decade, KENC has grown from an engineering subcontractor to taking on larger and larger scopes. Today, we can take full responsibility for the functionality of the equipment we design. Being able to align multiple parties into an efficient ‘production machine’ was one of the main reasons our client trusted us to deliver this equipment within scope and on-time.

The HSD basket ready for load-out

COMMISSIONING OF THE SYSTEM

After every component was connected and tested according to the classification rules, we entered the last phase: installing, testing and commissioning of the Noise Mitigation Deployment System, keeping in mind all daily processes on board and the vessel’s tight deadline to sail out.Eric Buining, managing director of KENC: “I’m very proud of our team and our subcontractors. Delivering the NMDS was a challenging, but very successful project. It clearly underlines our design and manufacturing expertise and the fact that we are able to handle large scopes for offshore projects.”

Hydro sound damper commissioning

LET’S FIND OUT WHAT WE CAN DO TOGETHER

We love to hear from you! Give me a call or send an e-mail.

Vincent Vinkoert

Business Development Manager

+31 6 308 469 86 | vincent.vinkoert@kenc.nl