PRE-PILING TEMPLATE

THE MARKET

Offshore wind turbines are increasing in size and moving to deeper waters further offshore. Therefore jacket foundations are used to support the next generation WTG’s. For efficient installation of the jacket foundation, a pre-piling template enables piles to be driven into the seabed. This speeds up the installation process and increases the accuracy of offshore piling operations. However, there are more challenges to conquer…

GROWING PAINS

When turbines are increasing in size this also means they need to be placed further apart from each other. Chances are you’ll meet a variety of soil circumstances. This can result in different dimensions of the foundations in the same wind farm. Looking at the massive impact on the tool during piling operations, a pre-piling template needs to be extremely robust and reliable. You also want the template to resist the strong impact of waves.

OUR SOLUTION

KENC’s pre-piling template meets the challenges of tomorrow. The structure is adjustable, lightweight, and robust. Ultimate accuracy is assured during operations.

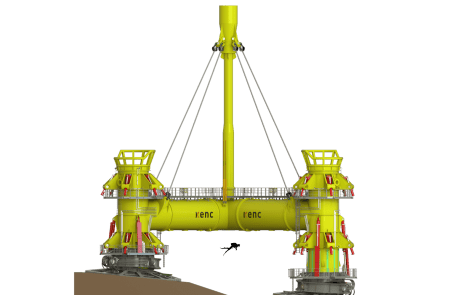

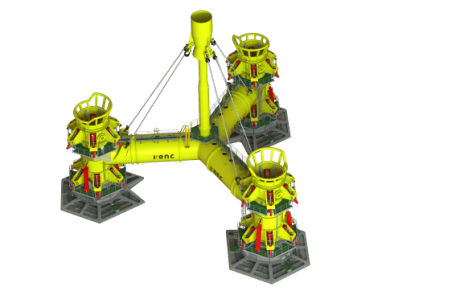

ADJUSTABLE FRAME

KENC’s pre-piling template installs foundation piles for 3- or 4-legged offshore wind turbine jackets within strict dimensional tolerances by using a hydro hammer or fibro drill. The piling frame is suitable for a range of different pile diameters and center to center (CtC) distances and can be configured for both 3- and 4-leg setups. The pockets are equipped with hydraulically separate adjustable rollers which enable an accurate adjustment of the pile inclination and CtC distances.

LIGHT WEIGHT & ROBUST

The innovative tubular design of the frame sections enables a modular setup that is lightweight, robust, and easily scalable with a minimum of buoyancy and with minimization of fatigue critical connections.

ACCURATE LEVELING

The PPT levels itself on the seabed through vertical traveling mud mats which are driven by hydraulic cylinders. The mud mats are equipped with robust gimbal joints which means that they are passively self-adjusting to the seabed inclination for maximum utilization of the seabed bearing capacity. The gimbal joint has a very low tilting resistance and is insensitive to pollution. The mud mats are provided with a spooling mechanism that contributes to a reduction of the release forces of the mud mats. Components and equipment are positioned within the tubular frame sections where possible, making them less vulnerable and easily accessible for operators in a safe work position.

FEATURES

SPECS

LET’S FIND OUT WHAT WE CAN DO TOGETHER

We love to hear from you! Give me a call or send an e-mail.

Vincent Vinkoert

Business Development Manager

+31 6 308 469 86 | vincent.vinkoert@kenc.nl